You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you doing with homebrew today?

- Thread starter BOB357

- Start date

That’s gorgeous! please shoot me your recipe.

yeah drier January for me. Skip most of the week days. We are out of school until Thursday due to flu, attendance district wide is below the threshold to pay for having school since the state pays for that. So I may sneak some this week. I skipped yesterday so I’m owed a day haha

- Joined

- Jun 27, 2019

- Messages

- 2,605

- Reaction score

- 7,874

- Points

- 113

Thanks. My English Porter has been a work in progress to say the least. My goal is to separate this Porter from my house Stout. I want to keep the roasty, coffee flavors in the Stout and aim for more caramel/toffee/chocolate in the Porter. I feel like every time I make it I lean too far in one direction or the other. I either end up with too much roast or I make a nice Brown Ale.That’s gorgeous! please shoot me your recipe.

yeah drier January for me. Skip most of the week days. We are out of school until Thursday due to flu, attendance district wide is below the threshold to pay for having school since the state pays for that. So I may sneak some this week. I skipped yesterday so I’m owed a day haha

https://www.brewersfriend.com/homebrew/recipe/view/944534/brotherhood-porter

- Joined

- Jul 4, 2022

- Messages

- 2,206

- Reaction score

- 3,544

- Points

- 113

73% from 1968? Wow!

- Joined

- Jul 4, 2022

- Messages

- 2,206

- Reaction score

- 3,544

- Points

- 113

Trying to keep good fermentation temps in the garage. I did hear a weird noise earlier. It was the bubbling coming from my 1" blow off tube into a growler. Holy shit, that is one active yeast! Good thing I didn't use the airlock.

- Joined

- Jun 27, 2019

- Messages

- 2,605

- Reaction score

- 7,874

- Points

- 113

Yeah I agree. I was expecting more like 65-68% for a Porter.73% from 1968? Wow!

Moist January.So not Dry January, just “Drier” January. A smart approach.

- Joined

- Jul 19, 2019

- Messages

- 2,270

- Reaction score

- 5,760

- Points

- 113

Yesterday kegged up the Winter lager and my Saison for a few weeks of lagering and keg conditioning respectively. Trying to build my inventory of ready to go brews when I return to imbibing alcohol. January has been a "dewy" month until all kegs were empty. Today, breakdown the kegerator and get it all cleaned up and give it a "vacation"

Bottled rest of a keg of Helles brewed to share with a buddy.

Very Cool Clint yes a perfect opportunity to give it a once over.Yesterday kegged up the Winter lager and my Saison for a few weeks of lagering and keg conditioning respectively. Trying to build my inventory of ready to go brews when I return to imbibing alcohol. January has been a "dewy" month until all kegs were empty. Today, breakdown the kegerator and get it all cleaned up and give it a "vacation"

It's been too long since I've done the same with my keezer.

I honestly did not see that coming, but I appreciate a good joke.Obviously an Ice Beer...

- Joined

- Jun 27, 2019

- Messages

- 2,605

- Reaction score

- 7,874

- Points

- 113

Changing all the O-Rings on my keg posts! That’s what I’m doing today.

I was just trying to tap a Porter and for the life of me I could not push the disconnect down on the out post. Wtf? I’ve been a muttonhead before and reversed the keg posts, but not this time. I tried spraying the post with StarSan and when that didn’t work, I tried keg lube on the post O-Ring. No help.

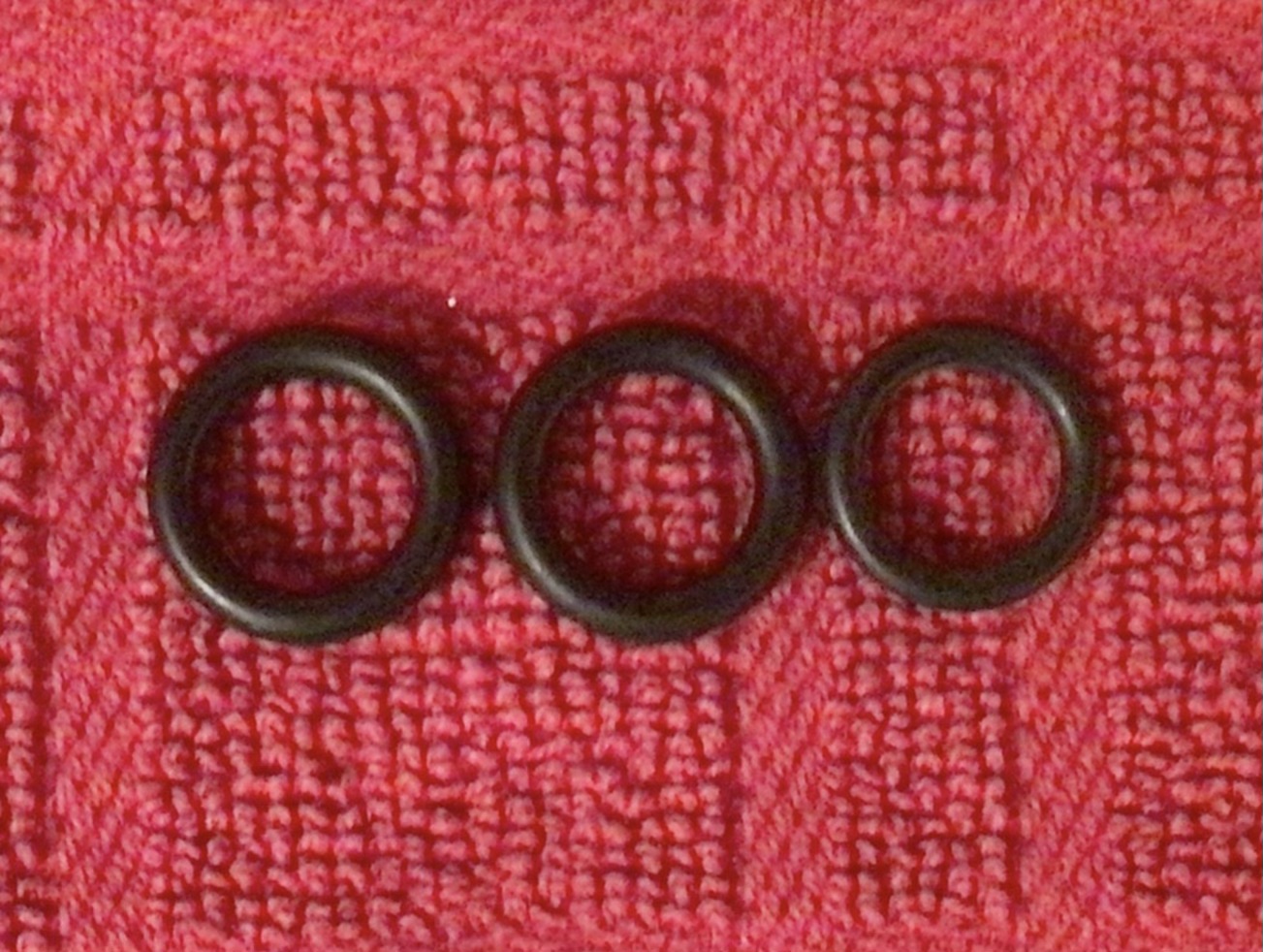

Finally I took the O-Ring off and compared it to two others, one used and one brand new. The two old O-Rings have expanded so much that neither would allow me to snap the disconnect In place. The new O-Ring worked like a charm. Might not seem like much, but this is all it took. Check out the size difference between the 2 old ones and the new one.

I was just trying to tap a Porter and for the life of me I could not push the disconnect down on the out post. Wtf? I’ve been a muttonhead before and reversed the keg posts, but not this time. I tried spraying the post with StarSan and when that didn’t work, I tried keg lube on the post O-Ring. No help.

Finally I took the O-Ring off and compared it to two others, one used and one brand new. The two old O-Rings have expanded so much that neither would allow me to snap the disconnect In place. The new O-Ring worked like a charm. Might not seem like much, but this is all it took. Check out the size difference between the 2 old ones and the new one.

Wowie problem solved yup I try and lube them orings up as much as possible.Changing all the O-Rings on my keg posts! That’s what I’m doing today.

I was just trying to tap a Porter and for the life of me I could not push the disconnect down on the out post. Wtf? I’ve been a muttonhead before and reversed the keg posts, but not this time. I tried spraying the post with StarSan and when that didn’t work, I tried keg lube on the post O-Ring. No help.

Finally I took the O-Ring off and compared it to two others, one used and one brand new. The two old O-Rings have expanded so much that neither would allow me to snap the disconnect In place. The new O-Ring worked like a charm. Might not seem like much, but this is all it took. Check out the size difference between the 2 old ones and the new one.

View attachment 28083

- Joined

- Jan 27, 2019

- Messages

- 4,492

- Reaction score

- 10,614

- Points

- 113

I got something like that on my new oxebar tapping heads.Changing all the O-Rings on my keg posts! That’s what I’m doing today.

I was just trying to tap a Porter and for the life of me I could not push the disconnect down on the out post. Wtf? I’ve been a muttonhead before and reversed the keg posts, but not this time. I tried spraying the post with StarSan and when that didn’t work, I tried keg lube on the post O-Ring. No help.

Finally I took the O-Ring off and compared it to two others, one used and one brand new. The two old O-Rings have expanded so much that neither would allow me to snap the disconnect In place. The new O-Ring worked like a charm. Might not seem like much, but this is all it took. Check out the size difference between the 2 old ones and the new one.

View attachment 28083

2 very easy to connect and 2 are a pain.

I noticed the difference in O-ring size (and colour)

I was going to ask a question about it.

I got O rings lying around. Can I just replace? I figure they don't need to be food safe as they won't touch the beer?

After bottling the cider, I pulled a sample of Red Wheat for Winter. After 20 days, gravity is at 1.010, 2 points lower than recipe projection. Given that OG was 2 points below projection, abv is right on at 5%. Color was the usual amber, and the taste was fine, if a tad spicy. Since the beer is ready, it will go in the keg tomorrow. This evening, I took apart the posts and sanitized them, then put them back in place and filled the keg with sanitizer. Tomorrow I will check all of the connections to see if there are any leaks. If all checks out, then I will fill the keg.

- Joined

- Jan 27, 2019

- Messages

- 4,492

- Reaction score

- 10,614

- Points

- 113

Exciting @Herm brews !

I still gotta decide which to bottle and which to keg between simple cider and low abv ipa

I think cider will go in the keg as that fermenter has no spigot (well, it has, but it is in use as a blow off valve)

Although I could bottle using my auto siphon.. I've done that plenty times before

I still gotta decide which to bottle and which to keg between simple cider and low abv ipa

I think cider will go in the keg as that fermenter has no spigot (well, it has, but it is in use as a blow off valve)

Although I could bottle using my auto siphon.. I've done that plenty times before

- Joined

- Mar 14, 2018

- Messages

- 9,466

- Reaction score

- 17,250

- Points

- 113

Very exciting!After bottling the cider, I pulled a sample of Red Wheat for Winter. After 20 days, gravity is at 1.010, 2 points lower than recipe projection. Given that OG was 2 points below projection, abv is right on at 5%. Color was the usual amber, and the taste was fine, if a tad spicy. Since the beer is ready, it will go in the keg tomorrow. This evening, I took apart the posts and sanitized them, then put them back in place and filled the keg with sanitizer. Tomorrow I will check all of the connections to see if there are any leaks. If all checks out, then I will fill the keg.