Well I'm about 15 minutes into the mash and my newly modified HEATED mash tun is working according to plan. Going to hold at 152 for 45 minutes and let the temp ramp up tp 165 over 30 minutes before sparge.

- Home

- Forums

- Home Brewing Forum

- General Brewing Discussions

- Brewer’s Friend Community Recipe Discussion

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Q1 2021 Community Recipe by HighVoltageMan!

- Thread starter Sunfire96

- Start date

-

- Tags

- community recipe

- Joined

- Mar 14, 2018

- Messages

- 9,425

- Reaction score

- 17,165

- Points

- 113

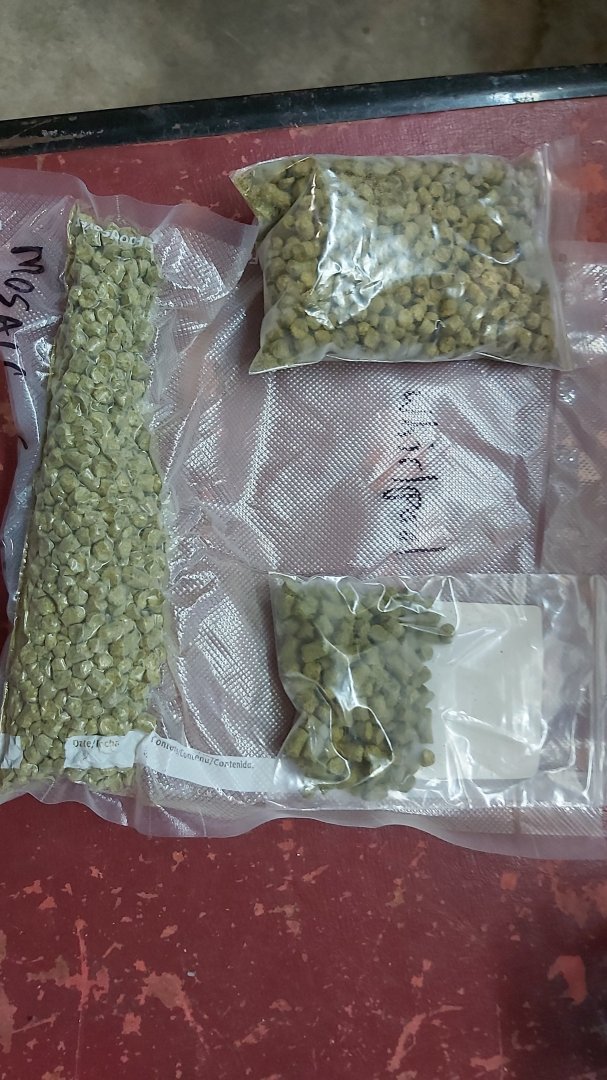

Brewed today as well, all done except that I am circulating PBW at 77C for a time. Here are my whirlpool hops, before, and after. They smell so good, it is a shame to bin them after

- Joined

- Feb 2, 2015

- Messages

- 1,698

- Reaction score

- 2,674

- Points

- 113

Is that 12 ounces? It looks like more.

I split the ibu’s three ways with 4 ounces each of Mosaic and Citra along with 8 ounces of whole Mandarina. Just finished the hopstand. Smells awesome.Is that 12 ounces? It looks like more.

It was a gallon bucket, 8 ounces whole Mandarina, 4 ounces of Citra pellets and 4 of Mosaic pellets.(have a ton of Mandarina that I need to use)I thought that as well, maybe that bucket isn't as big as it looks...

Mines looking like this this arvo

Nice healthy fermentation.

Nice healthy fermentation.

- Joined

- Mar 23, 2018

- Messages

- 1,116

- Reaction score

- 2,170

- Points

- 113

Well, Extractor completed yesterday and brew started today. Mashing in and Lautering done. Currently 20 minutes to go before boil is finished. Then cool to 77C , bung in the Citra and Mosaic - an industrial bucket load by usual standards but essential for this recipe. I hope my pump doesn't get clogged with the whirlpool.

Now to whirlpool...

Now to whirlpool...

- Joined

- Mar 23, 2018

- Messages

- 1,116

- Reaction score

- 2,170

- Points

- 113

Well all done. Hit the PreBoil SG at 1.054 but not the volume expected - Grain absorption needs updating I think. Sample post boil OG lower at 1.050 - I had topped up volume a bit. 17Lt in the fermenter. Tilt reporting 1.037! maybe needing calibrating bit I can't be arsed to do it as I will take SG when I dry hop. Looks like primeordial soup but it's in the fermentation fridge set to 18.7C. Fingers crossed.

New boil now on Thursday. What shall I brew? Something with Vienna and Red X in it I think - need to use them up.

The extractor fan is NOT powerful enough. A lot of the steam that made it up the ducting condensed in the dips. At least not much dripped back into the pot which would be bad news.

New boil now on Thursday. What shall I brew? Something with Vienna and Red X in it I think - need to use them up.

The extractor fan is NOT powerful enough. A lot of the steam that made it up the ducting condensed in the dips. At least not much dripped back into the pot which would be bad news.

Last edited:

This verdant yeast throws a big krausen havnt had one like this in awhile!

Mashed on Friday & Boiled on Saturday. Starter wasn't ready until Sunday. I used WLP007 instead & we're cooking this morning. My pre boil SG was 1.040 & 1.050 going into fermentation. Day 2 of fermentation is rolling now @ 62 F. @HighVoltageMan! Made a comment about WLP007 was prone to be an active fermenter so I hooked up a Blow Off hose to contain the mess but no blow off. No problem there. Looking forward to 1st pour.

- Joined

- Feb 2, 2015

- Messages

- 1,698

- Reaction score

- 2,674

- Points

- 113

I used 007 too. It is not a puker. It behaves itself with no volcanoes. It’s an awesome yeast, a real workhorse.

Hey @HighVoltageMan!, I was wondering how you determined the hop utilization rate of 3% during the whirlpool?

You get any condensation in the extraction tube there Alan?Well, Extractor completed yesterday and brew started today. Mashing in and Lautering done. Currently 20 minutes to go before boil is finished. Then cool to 77C , bung in the Citra and Mosaic - an industrial bucket load by usual standards but essential for this recipe. I hope my pump doesn't get clogged with the whirlpool.

View attachment 13757

View attachment 13758

Now to whirlpool...

Nice recirculation system very ingenious you get any extra efficiency?

- Joined

- Mar 23, 2018

- Messages

- 1,116

- Reaction score

- 2,170

- Points

- 113

Yes big pools in the dips as thr fan could not extract the steam fast enough and that the trunking is not insulated enough. System scrapped but was worth the try. Yes the pump helps me get much crearer wort as I'm lautering over 20 minutes or so until the grain bed settles and filters well. I dont use a normal bazooka though. I use a 15in flexible stainless steel hose with the inner rubber hose removed and the farther end removed. I use the same pump for whirlpool.You get any condensation in the extraction tube there Alan?

Nice recirculation system very ingenious you get any extra efficiency?

- Joined

- Mar 14, 2018

- Messages

- 9,425

- Reaction score

- 17,165

- Points

- 113

The ph rises during the lauter after the mash. Most home brewers watch the pH in the mash and think that’s it. The pH should be watch through the entire process; mash, boil and fermenter. The most important pH is at pitch. Lighter beers should be at 5.2 or lower, darker beers tend to be higher, 5.3-5.4. The yeast will excrete acids during fermentation to drop the pH of the beer. This not only helps the yeast to respirate (bring nutrients in and co2/alcohol out of cell) but it also benefits the beer. At 5.2 most yeast will be able to excrete acid they need to have a healthy fermentation. High pH on lighter beers like IPA/PA will cause the beer to have a harsh bitterness/mouthfeel, malt flavors can be dull or reduced. Each strain of yeast has a sweet spot for its finished pH. Kolsch yeast can go down as low as 3.9, while Chico strains can be as high as 4.6. The same wort fermented with these 2 yeast will produce vastly different beers with a different pH.

The bottom line is that the pitch pH should be between 5-5.2 for lighter beers. The yeast will do the rest. Sometimes the pH rises too much after dry hopping and what was once a nice beer, is now rough. The pH can be adjust post fermentation, but the acid additions can’t be so much that the acid can make the beer have a tart finish.

The finish pH of the beer has a big impact on the overall quality and getting a handle on it will improve the overall beer.

HVM

I have had a couple of pH meters and neither has been worth a sh*t.

What meter do you have, and how simple/difficult is it to calibrate?

- Joined

- Mar 14, 2018

- Messages

- 9,425

- Reaction score

- 17,165

- Points

- 113

I can confirm hop absorption was higher than usual, but probably normal considering nearly a pound of hops was in there.

Brew day went well, hit my strike temp dead on, and held it within a couple of degrees, stepped up to 162 and sparged with 170 water. Acidified with 10% phosphoric acid (just used 8.8 times as much) to good effect. Below is my boil. At flame out (well, 'switch off") I lowered the temperature a bit to maybe 180, added the hops (in bags) and continued to cool it using the chiller to 170, and let it sit 20 minutes. Decanted just under 21 quarts to the fermenter, pitched at 74 F (went in at 92 F, counterflow chiller was off its game a bit, I think I know why) and today it is happily bubbling away at 67 F.

Hit my OG perfectly at 1.058, could've easily fit more grain in there but that made stirring the mash really easy. In a BZ35 I used the malt pipe but not the false bottom, and recirculated at almost full speed the whole time. As usual (for me) the temp controller was set at 158 to hold 150.

You can watch progress here:

What efficiency are you getting with your Brewzilla?

- Joined

- May 10, 2019

- Messages

- 1,261

- Reaction score

- 2,815

- Points

- 113

Yes big pools in the dips as thr fan could not extract the steam fast enough and that the trunking is not insulated enough. System scrapped but was worth the try. Yes the pump helps me get much crearer wort as I'm lautering over 20 minutes or so until the grain bed settles and filters well. I dont use a normal bazooka though. I use a 15in flexible stainless steel hose with the inner rubber hose removed and the farther end removed. I use the same pump for whirlpool.

I tried t vent from my basement too as there is no real ventilation. That is why I had to come up with this one. Recover almost a gallon of condensate every batch.

https://www.brewersfriend.com/forum/threads/boiling-indoors.13713/