I've go an old 60s(?) 1/6hp out in the garage, used to power my great great uncles bench grinder. Pretty sure I could use it to build a drive for the mill. Probably go like 8:1 reduction with pullys.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

motorized mill

- Thread starter Minbari

- Start date

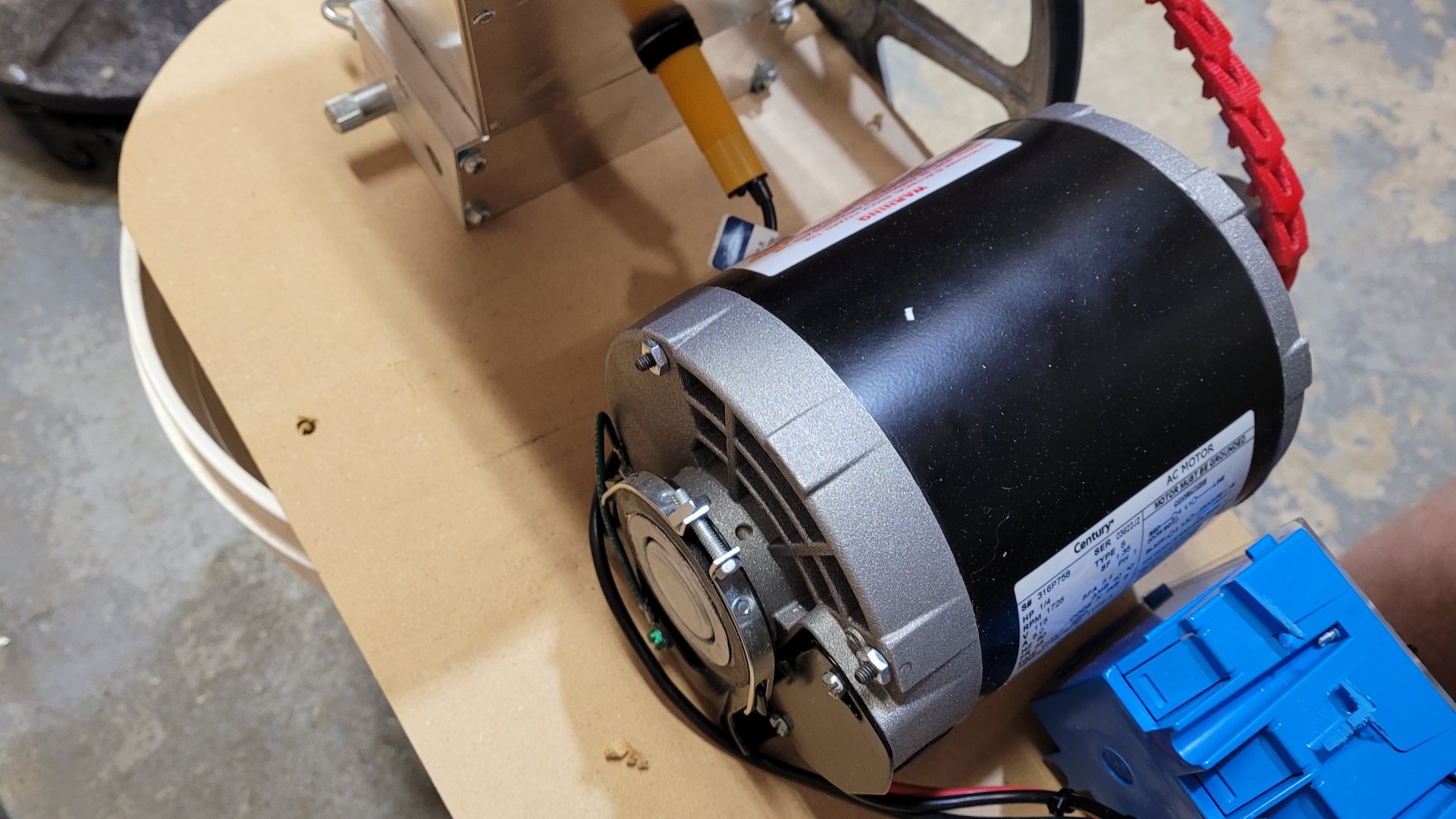

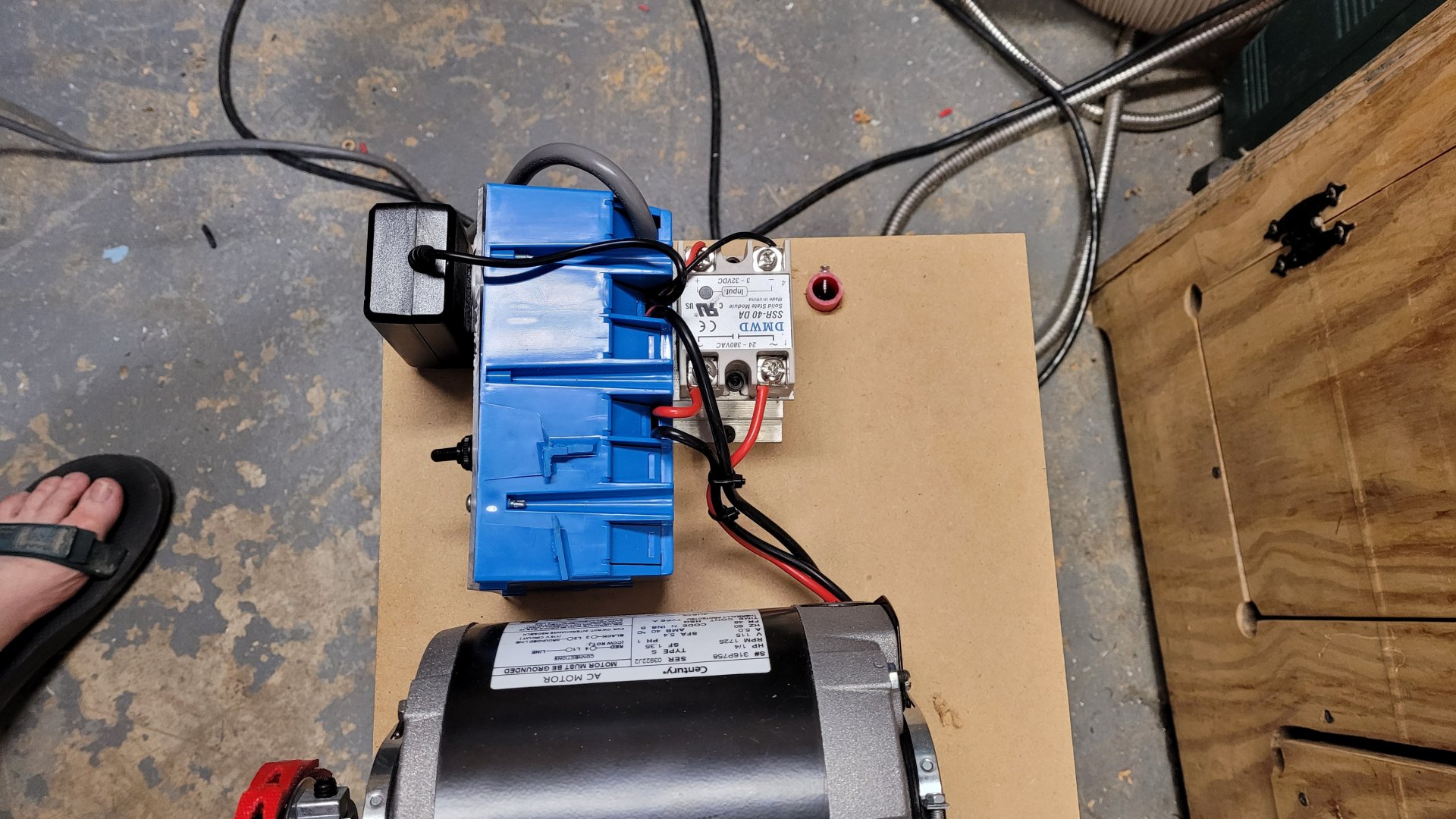

Ok got me an induction ac motor

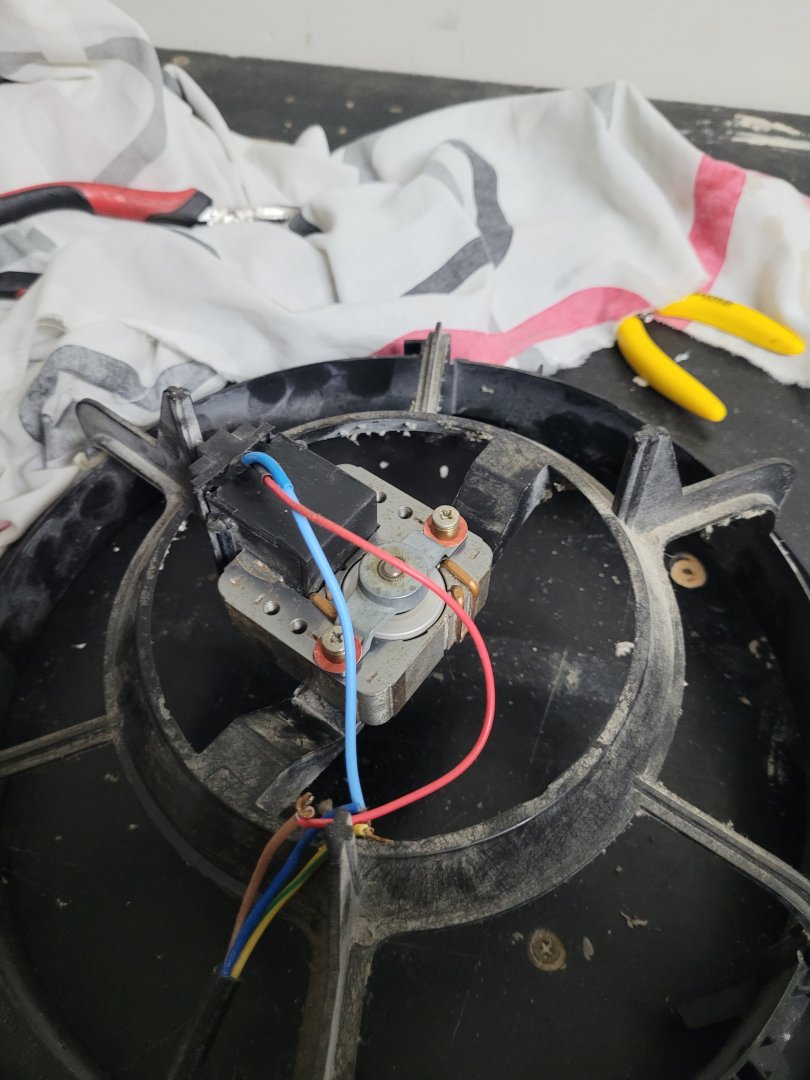

My bathroom ceiling exhaust fan was stuck well luckily my dodgy diy skills got this baby working again.

Yup all working again bit of a clean up and wd40 she's all good baby!

My bathroom ceiling exhaust fan was stuck well luckily my dodgy diy skills got this baby working again.

Yup all working again bit of a clean up and wd40 she's all good baby!

Last edited:

- Joined

- Mar 31, 2021

- Messages

- 3,952

- Reaction score

- 5,894

- Points

- 113

lol, all about the gearing!Might be a bit underpowered for the mill.

Too right.Might be a bit underpowered for the mill.

Na it's been on my "List"

So took it apart it was ceased up from all that steam gotta stop pi$$ing in the shower (ok too much info lol)

But it's back in and working better than it ever has.

See that's we're dicking around with electronics gets ya not afraid to take it apart.

- Joined

- Mar 31, 2021

- Messages

- 3,952

- Reaction score

- 5,894

- Points

- 113

Last edited:

- Joined

- Jan 27, 2019

- Messages

- 4,375

- Reaction score

- 10,421

- Points

- 113

I use hand power and when the feeder is empty the power source stops.

All you need to do is feed it beer

I only do small batches, so can't even be bothered to go find my drill.

2 kg, double milled takes less than 10 minutes.

Me remembering and finding my drill will take longer

All you need to do is feed it beer

I only do small batches, so can't even be bothered to go find my drill.

2 kg, double milled takes less than 10 minutes.

Me remembering and finding my drill will take longer

- Joined

- Mar 31, 2021

- Messages

- 3,952

- Reaction score

- 5,894

- Points

- 113

Here it is finished. One project that actually works the way I designed it on the first try.

Edit: I will admit, I hooked up the SSR wrong on the first try and fried it. the 3-30VDC side (for switching) doesnt like it when you connect 120VAC to it

Here is a video of it in action:

https://fb.watch/f155eZKCrj/

Edit: I will admit, I hooked up the SSR wrong on the first try and fried it. the 3-30VDC side (for switching) doesnt like it when you connect 120VAC to it

Here is a video of it in action:

https://fb.watch/f155eZKCrj/

Last edited:

- Joined

- Oct 18, 2015

- Messages

- 8

- Reaction score

- 12

- Points

- 3

I made mine using an old motor from a drill press.Ha who has done it here and what kind of motor did you use?

I am looking at some of the gear drive motors. But have no idea if they have enough power. One is a 3:1 with 1.5ft-lbs torque @450rpm. Looking to reduce that further with pulleys, 4:1. So would have 6 ft-lbs.

Thoughts?

- Joined

- Mar 31, 2021

- Messages

- 3,952

- Reaction score

- 5,894

- Points

- 113

I thought about that, but I bet my wife wouldn't let me buy a new drill press lolI made mine using an old motor from a drill press.

I run my Hullwrecker mill with a Milwaukee M18 compact drill set on low(1). Tears through the grain pretty fast. Probably build a stand for it someday.

I use a compact drill on mine as well. A full charge will do two brews. Beats turning the handle which was not good for my dodgy wrists (joint fusions).

everything I read said that 300RPM was what you wanted for my mill.

I have been using my drill on low speed gear and that is about 450 RPM. seemed to work, but if it will mill with out having to hold a drill, then slower wont hurt. its not like I am milling 500 lbs of grain.

Why would a home brewer grind 500lbs of grain. Capturing the aroma of freshly ground grain in the mash cannot be beaten. One of the big benefits of my getting my Mill was to do that. Also unground grain keeps much longer.

- Joined

- Mar 31, 2021

- Messages

- 3,952

- Reaction score

- 5,894

- Points

- 113

my point was I dont do that.Why would a home brewer grind 500lbs of grain. Capturing the aroma of freshly ground grain in the mash cannot be beaten. One of the big benefits of my getting my Mill was to do that. Also unground grain keeps much longer.

- Joined

- Mar 12, 2017

- Messages

- 2,338

- Reaction score

- 4,900

- Points

- 113

Why would a home brewer grind 500lbs of grain. Capturing the aroma of freshly ground grain in the mash cannot be beaten. One of the big benefits of my getting my Mill was to do that. Also unground grain keeps much longer.

I mill my grain at the LHBS. The grain room smells fantastic. Even when I stop in and don't have to mill any grain, I still stop in the grain room for a whiff.

Just ordered a 10:1 cast iron gearbox off ebay, hook this up to the old motor I have in the garage and it'll give me 175 rpm and an effective 6hp. That ought to turn a mill.

https://www.ebay.com/itm/4035073873.../nDfEBWoAqG6iCoTOJlvIgLV8=|tkp:Bk9SR7S8g5TeYA

https://www.ebay.com/itm/4035073873.../nDfEBWoAqG6iCoTOJlvIgLV8=|tkp:Bk9SR7S8g5TeYA