Hello, I'm very new to brewing with 2 completed brews under my belt, both one gallon all-grain recipes. I would like to mash and brew in the same kettle, but was wondering if I could use several small grain bags for my mash (I don't want to commit to BIAB due to low efficiency). If I have 1.8-2.5 lbs of milled grain in multiple small bags (about 8"x8") and mash at 150F for an hour, could I lift and place the bags into a strainer over the brew kettle, and then sparge and recirculate over them like normal? Would the size of the bags limit the amount of sugar extracted from the grain? Again, I'm very new and trying to find a process that works best for me and my small space/equipment  thank you so much!

thank you so much!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Want to change my mash/sparge setup for small batches

- Thread starter Sunfire96

- Start date

For small batches, BIAB works very well. I brew 2.5 gallon batches. I buy elastic top brew bags on Amazon (3 for $7). I get several uses from each bag. You can then mash at full volume and eliminate the sparge step or mash at a lower volume and sparge as you described.

Thank you! I don't currently have a brew kettle large enough for BIAB for a one gallon batch. My hope is to mash and boil in the same kettle, because it's the largest cooking pot I have.

- Joined

- Jul 19, 2019

- Messages

- 2,321

- Reaction score

- 5,940

- Points

- 113

I only use the BIAB method and I make 2, 3 and 5 gallon batches. I would put all of your grain in one bag. I also squeeze the bag to get as much of the liquid as possible.

FYI, efficiency at our scale doesn't really matter as long as you get it the same every time. You're talking maybe 100-200g of additional grain to save yourself a lot of hassle.

That's a good point, thanks!

- Joined

- Jul 16, 2012

- Messages

- 10,254

- Reaction score

- 8,366

- Points

- 113

Efficiency is such a low priority for us, I don't even put it on my priority list of factors to consider in brewing. It becomes important in commercial batches where cost is a factor but not really for us. Here's an example: My system works better with a coarser crush, known to reduce efficiency. I can fight a stuck mash or spend 50 cents to a dollar more on grain. Why would I fight a stuck mash for that amount of money?

Welp, I forgot to recirculate the wort after sparging, mistakes happen. I think my efficiency would have been okay, not great, with recirculating, but as is, my mash efficiency was about 36% lol not a big deal, just less boozy than projected. I think I'll abandon my small bag idea for now, and go back to sparging in a strainer (I'm only doing 1 gallon batches). I also had more evaporation during the boil than expected so I'm hoping to get a bigger kettle for next time and start with more liquid. Thanks again for everyone's advice!

- Joined

- Mar 27, 2020

- Messages

- 37

- Reaction score

- 40

- Points

- 33

Unless you brew with an induction hob inside and then you have problems getting things into and out of the kettle when it is on the stove!

#lessonslearned #apartmentbrewing

Also, BIAB brewer here with a 20L kettle and recirculation setup. I can do a 10L (fermenter) batch easily enough with a minimal/no sparge and it works well enough. As above, it is just the right size for the height of the stove and the power of the hob. Any bigger on the batch size and I would have to hump it down off the hob to lift stuff in and out of and i genuinely think that the hob itself would have a hard time getting things to a boil.

FWIW, I measured the efficiency I get right now and it is knocking around 72%, which is not too bad for a small batch setup I think

#lessonslearned #apartmentbrewing

Also, BIAB brewer here with a 20L kettle and recirculation setup. I can do a 10L (fermenter) batch easily enough with a minimal/no sparge and it works well enough. As above, it is just the right size for the height of the stove and the power of the hob. Any bigger on the batch size and I would have to hump it down off the hob to lift stuff in and out of and i genuinely think that the hob itself would have a hard time getting things to a boil.

FWIW, I measured the efficiency I get right now and it is knocking around 72%, which is not too bad for a small batch setup I think

- Joined

- Jul 27, 2017

- Messages

- 4,730

- Reaction score

- 4,609

- Points

- 113

I started with a kettle I got for free and I think it's around 3 gallons. I've never actually measured it but it worked reasonably well when I was messing around with extract brewing. My wife had a 6 gallon aluminum kettle I moved to when I got a propane burner and other than boil overs it worked really well. I use a 2/3 vessel setup so I have a 65L Coleman cooler for my mash tun and it works well, I got it for $20 so I've long since made the return on my investment.

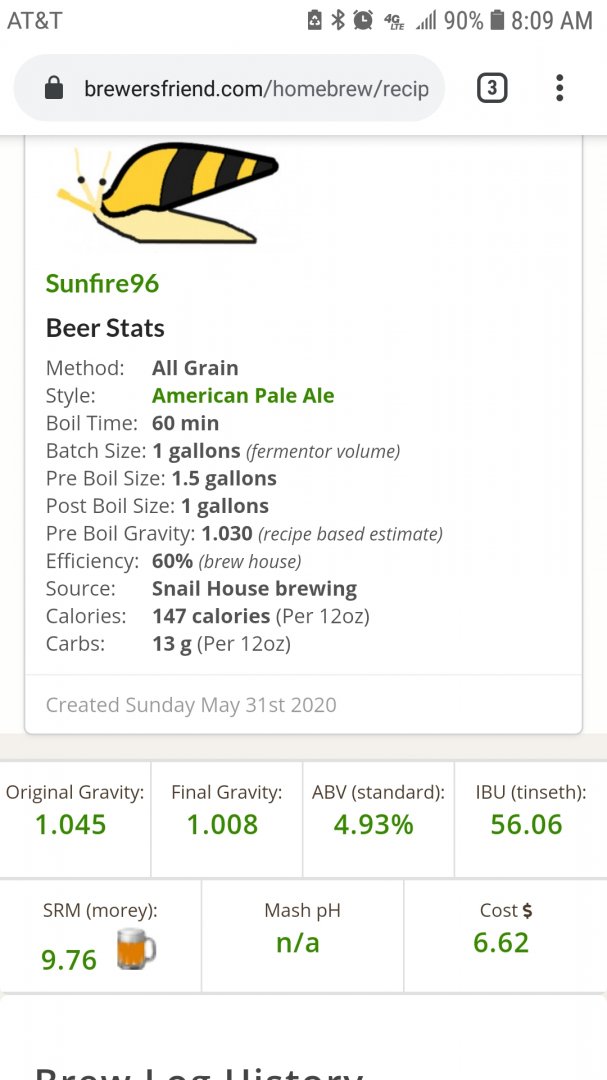

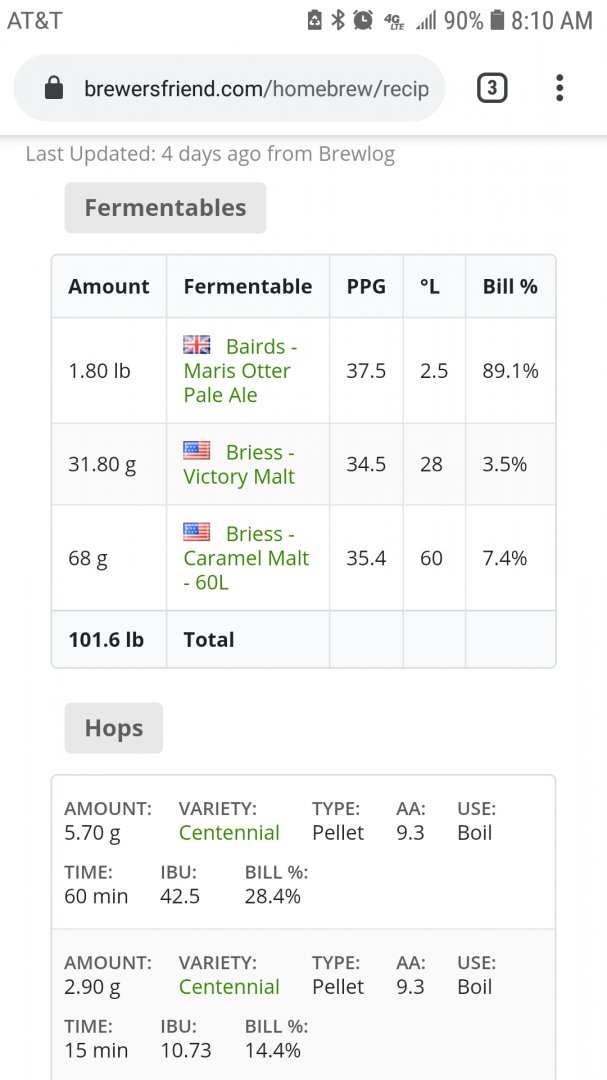

Well the grain in multiple bags idea was not great in application. Will scrap the idea for now. I'm trying to resolve a new issue that popped up in my last batch. I think my mash temp was a little low (145-150F, most in the 40s), and my yeast attenuated at 92%. Given the low sugar extraction from my mash (only about 36%), I was glad for the extra boost to ABV, but I'm worried it will taste too dry. The beer is an APA around 10 SRM, and it's supposed to have a strong malty backbone to carry the hoppiness. My final gravity was around 1.001, while projected FG was 1.008. Here are my thoughts for my next batch:

Mash higher for fewer fermentable sugars (150-154F)

Increase grist ratio to 1.5 qts/lb which increases my mash water (3 qts vs 2 qts previously)

Any thoughts or advice would be appreciated! Here's the recipe:

https://www.brewersfriend.com/homebrew/recipe/view/1004353/assassin-snail-pale-ale

Also the projected summary and grain bill are attached:

Mash higher for fewer fermentable sugars (150-154F)

Increase grist ratio to 1.5 qts/lb which increases my mash water (3 qts vs 2 qts previously)

Any thoughts or advice would be appreciated! Here's the recipe:

https://www.brewersfriend.com/homebrew/recipe/view/1004353/assassin-snail-pale-ale

Also the projected summary and grain bill are attached:

Bottling tomorrow, will let you know!!Did you take a sample? How did it taste. As long as it tastes decent, drinking your mistakes will inspire you to improve!

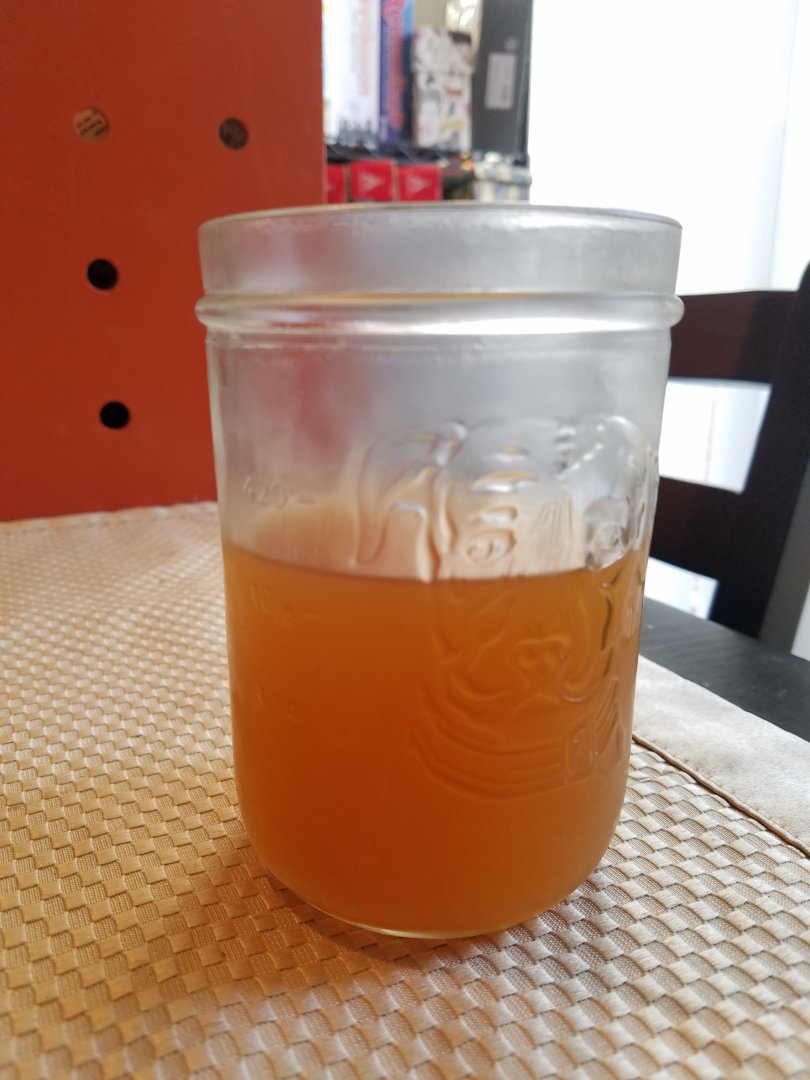

Overall, it tasted pretty good for a 3rd beer. It is quite bitter, and not very sweet. The color was spot on, though! This is the gravity sample and siphon leftovers after cooling