Friday, December 7th, 2012

Currently on special release in Q4 of 2012, Wyeast 3864 Belgian/Canadian Yeast comes from a brewery called Unibroue in Canada, and has some distinctive Belgian like properties you might be interested in.

Discovering Unibroue:

Years before I began to homebrew, we took a trip to Canada. It was a wonderful experience, and a memorable trip. Part of the fun was trying Canadian beers we hadn’t seen before.

A few years after this trip, we were having lunch with friends. It was a relaxing early summer day, and we were eating outside. A beer sounded like a perfect idea (when isn’t it?) . I was looking at the beer menu, noticed a Canadian beer on the menu, and ordered it. Our trip to Canada had been in the summer and the weather was conjuring up those fond memories. That was when I tried a Unibroue beer for the first time – a glass of Blanche de Chambly.

One of the key moments in my craft brew early days was having that glass of Blanche de Chambly. It is a Witbier brewed by Unibroue, a Canadian brewery located near Montreal in Chambly, Quebec.

They specialize in Belgian brews exclusively. I began to seek out all the Unibroue beers I could find. All were full of character and delicious. I still adore their beers.

Brewing With The Unibroue Yeast:

Fast forward a few years and I began homebrewing. I find out that Wyeast is offering the Unibroue strain in their 4th quarter Private Collection. I snatch up a few smack packs and was off to the races. That was 3 years ago. It’s back this quarter. If you like Belgians and you like Unibroue beers, I’d encourage you to try the strain before it’s gone again!

Here’s a link the yeast strain information for Wyeast 3864.

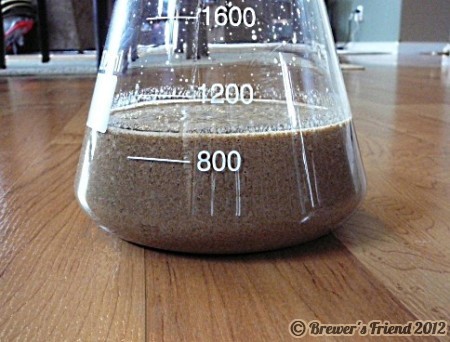

I’ve brewed three beer styles with it: witbier, tripel, and a Maudite clone (the oft circulated Ky’s Maudite recipe). It ferments in a rather civilized fashion, and wasn’t a climber – even on the wheat beer. I will comment that the Maudite clone is NOT a “nailed” clone. It is a delicious Belgian Dark Strong beer, however.

Jamil Z’s Tripel recipe is a fine foil for this yeast. Fermented in the mid of the temperature range, it produced a lot of character but did take awhile to smooth out. This time I’m going to try the lower end this time and see if it will take less aging to round out.

Recipes that work well with the Unibroue Yeast (Wyeast 3864 Belgian/Canadian Yeast):

Here’s a long cellared Ky’s Maudite in a glass. I had a few left in the back of my beer fridge. It is past its prime – the yeast strain character is fading – but it still tastes pretty good:

Unibroue Yeast Character:

I was thrilled to find that much of the “Unibroue character” is their proprietary yeast strain, and I was able to capture some of that essence in my batches. I’d describe the Unibroue strain as having a balanced and not overwhelming presentation of the typical hallmarks of Belgian yeasts: fruity character, spice, esters, and phenolics. At the high end of the fermentation range all these are amplified, especially the phenolics. I have found that if you overshoot the temperature range, aging can tame the flavors. This strain cellars well and retains it’s yeast character for 2 years or more if bottle conditioned and kept at cellar or refrigerator temperatures.

What I like best about the Unibroue strain is that it doesn’t hit you over the head with one particular note: it isn’t lots o’ spice, or lots ‘o fruit. It has these qualities present, but the flavor profile is not a “one trick pony” so to speak. There is also some acidity, which adds some focus and clarity to the Belgian character. Unibroue yeast is not as fruity as the Chimay strain (WLP500), not as spicy as the Achouffe strain (WLP550), and less civilized in character than the Westmalle strain (WLP530). In fact, some have speculated that Unibroue introduced some wild yeast from their Canadian region into a strain the founder brought over from Belgium.

To me the reason the strain is so delicious and also flexible is that it carries so many aspects of Belgian character – a complex flavor profile – but it does it in a refined and balanced manner. If you taste Blanche de Chambly (witbier), La Maudite (dark strong), and La Fin du Monde (tripel) side by side, you will easily detect the “Unibroue character” in each. However different each of these styles are, you will also find that yeast character appropriate and “at home” within that style’s profile.

This strain is very alcohol tolerant, and tastes good kegged or bottle conditioned. The highest gravity beer I’ve brewed with this strain thus far is about 9% – the Maudite clone, and I had no problems getting full carbonation in bottles with the original pitch.

I’ll add that Unibroue tends to carbonate their Tripels, Dark Strongs, etc. at the high end of the Belgian carbonation range. If you bottle condition, make sure you’re using strong bottles – most American bottles are suspect at holding those high carb levels and not becoming a bottle bomb.

I just purchased the equipment necessary for a frozen yeast bank so I won’t have to suffer the absence of this strain in off years. This is my favorite Belgian yeast, and I want to have it available!

If you like Belgians and you like Unibroue beers, I’d encourage you to try the strain. It is a very versatile Belgian strain and confers a strong but pleasant Belgian character in the beers I’ve brewed.

Posted in Beer Styles, Yeast Cultures | 5 Comments »