Saturday, July 9th, 2011

Fermenting crushed berries, grapes, and fruits can be a fun diversion from making beer. Home brewers who make beer already have all the equipment, except for a basket press. I tasted an amazing pear, blueberry, raspberry cider at a home brew club meeting last year. This inspired me to get more into fruity meads and wine. I tired making wine last fall. It is now in the bottle and going fast. It was totally worth it! Apples, Cherries, strawberries, blueberries, raspberries, blackberries, apricots, peaches… the list goes on, could all be experimented with.

The Basket Press:

Once again, you will need a new piece of equipment to make this work. I looked into the Do-It-Yourself solutions. A good basket press would take a lot of time to build, more time than I wanted to spend. Personally, I decided to buy a professionally made press. The pressure from the screw, alignment, and reliability were reasons I decided not to build my own. A small size is perfect for the small amounts I am working with.

(Action shot of the wine press.)

When shopping for a basket press, check out the Yakima Press Company.

Yakima Press Company sells high quality basket presses. If you are interested in pressing more than a few gallons, you will probably want a bigger press. All their products are 100% made in the USA.

Outline of the process to make Fruit Wine, Hard Cider, Sweet Mead:

1. Pick and wash your fruit. Get good quality fruit, it will shine through in the end result! Wine grapes are normally not washed, as it is too time consuming, and not necessary due to addition of sulfites later on. You’ll need a lot of fruit to get 1 gallon of juice. For example, with apples one bushel is about 42 pounds, and gives 2-3 gallons of juice. You can top this off with water and add sugar or honey to compensate. You don’t have to go with 100% juice to get a good result.

2. Crush the fruit to release the juices. Wine grapes are done with a de-stemmer / crusher. Raspberries and blueberries can be done easily by hand. Fruits like apples and pears can be chopped and then put through a food processor.

3. Run fruit through basket press. The harder you press, the more tannins and other harsh flavors will come through. I sampled for flavor as the crush went just to tell where I was at. When it gets hard to turn the press, that’s probably a good sign it is time to stop. Beware, this step is sticky and messy but tastes good.

Note: Red wine is an exception. With red wine pressing comes after fermentation, as the skins are what give red wine its color.

4. Add 1 campden tablet per gallon of juice. Let sit for 24 hours. This step kills off all the wild yeasts and other bad guys and creates a stable environment for the brewing yeast to take off.

Campden is the same thing as potassium or sodium metabisulfite. An equivalent solution can be created on your own (1 campden table in 1 gallon of water gives 67 ppm sulfur dioxide). Be careful not to over sulfite the batch!

Note: Again with wine from grapes the story is a little different. Sulfites are added right after the crush, targeting 60 ppm.

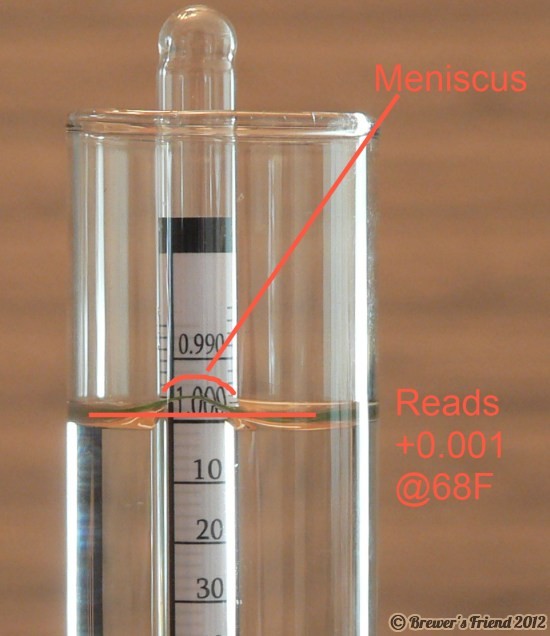

5. Measure gravity and volume. At this point, adjust with water and sugar or honey as desired so your target volume and alcohol level will be reached. This is going to vary widely depending on the recipe.

6. Transfer to carboy and pitch yeast. Yeast nutrient is a good idea. Dry mead yeast is very dry and will strip out all the sweetness. I’d recommend a sweet mead yeast on the first go.

7. Rack after primary fermentation is complete – could take up to a month. Expect to get a lot of trub, aka lees on the bottom of the carboy. Top off secondary with water or last year’s product. You may want to add more sulfites at this point to protect your new brew. The sulfites that were originally added are pretty much eliminated during primary fermentation.

8. Rack again and repeat every week or so until desired clarity is reached.

9. Bottle and age as desired.

10. Enjoy!

Posted in Equipment, Wine | No Comments »